EPOXY SPRAY COATING AND LINING

Epoxy is one of the best materials for coating and lining. Epoxy coated pipe are used in a wide variety of applications, such as potable water pipelines (Service temp. max 140° F (60° C)), casing, piling, and submarine lines.

To prevent internal corrosion, Epoxy lining is applied to pipes designed to convey and distribute dry gas, humid gas, kerosene and drinking, raw, industrial or waste water in addition to chemical products.

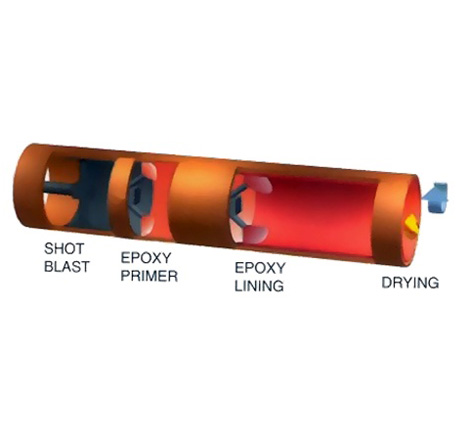

Epoxy Coating and Lining Process

The pipe is heated to eliminate humidity

The pipe surface is shot-blasted to remove scale and rust

The Epoxy primer coat is applied to the pipe surface

Epoxy paint is applied to the pipe surface

After application the pipe is

dried and cooled

Coating & Lining Process

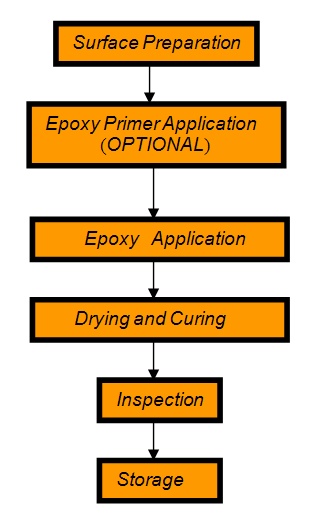

THE PROCESS:

“Prior to epoxy application, the pipe surface is blast-cleaned.

“According to type of epoxy, primer epoxy may be applied. Usually the epoxy is applied with epoxy primer to insure the best adhesion.

“After primer application, epoxy is applied to the pipe surface after a certain period of time determined by the epoxy material manufacturer.

The primer and epoxy are applied to the pipe surface with an airless spray system.

“After the epoxy coating/lining application, drying may be applied by one of heating methods to speed-up the curing of paint material and achieve higher production rate.

“When curing is completed, pipe ends are cleaned.

“Prior to pipe storage, the pipes are checked according to the QA/QC procedures.