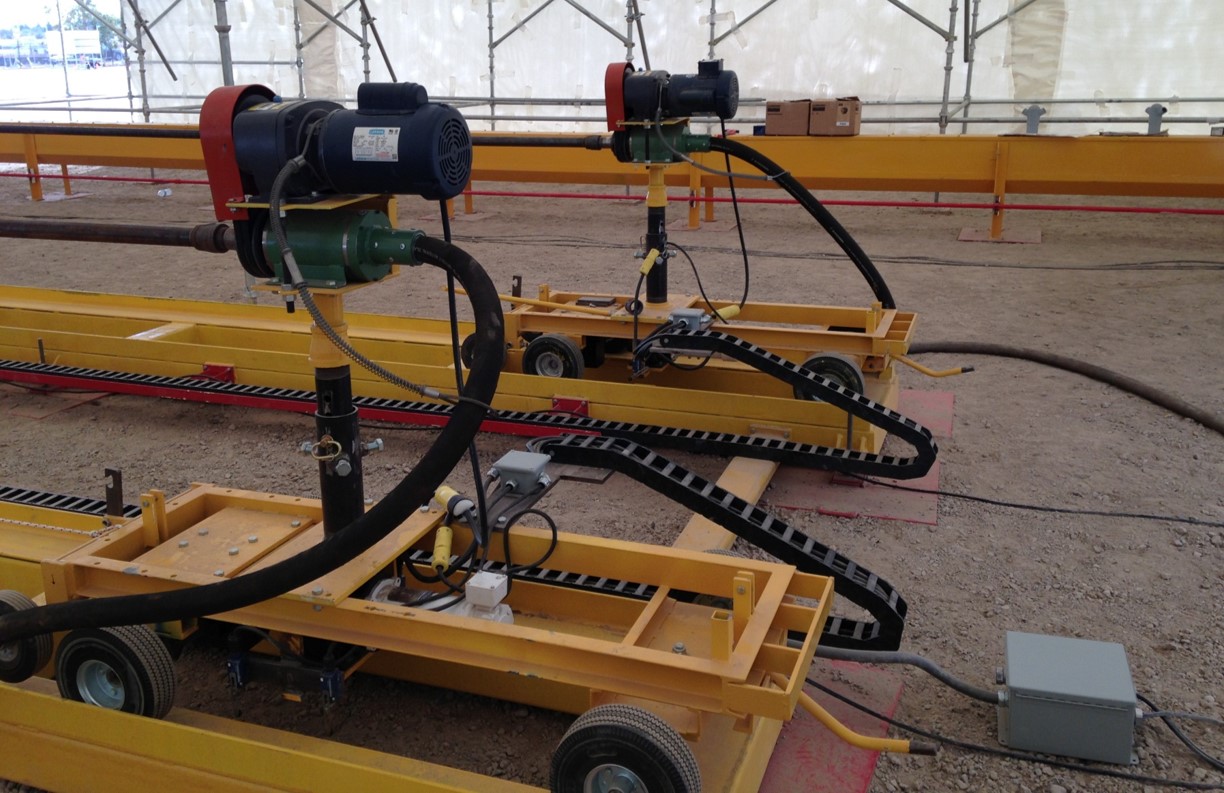

SPIRAL WELDSEAM PIPE MACHINE (SWPM)

PRD Company has responded to the needs of pipe producers since 1961. Today PRD Mills offer greater levels of manufacturing versatility — lowering the cost of producing pipe while increasing product offerings. The New Generation Spiral Weld Mill designs can provide pipe diameters from 200 to 4200 mm, with wall thicknesses ranging from 2 to...Read More

PRD-Blast Systems

Pacific Roller Die Company, Inc., world leader of large diameter pipe manufacturing technology, has the additional product line of PRD-Blast internal pipe blasting and coating systems. The self-propelled rotary stripping system is engineered to rapidly clean pipe interior surfaces down to the white metal without requiring personnel to enter the pipe. “Like a white tornado...Read More

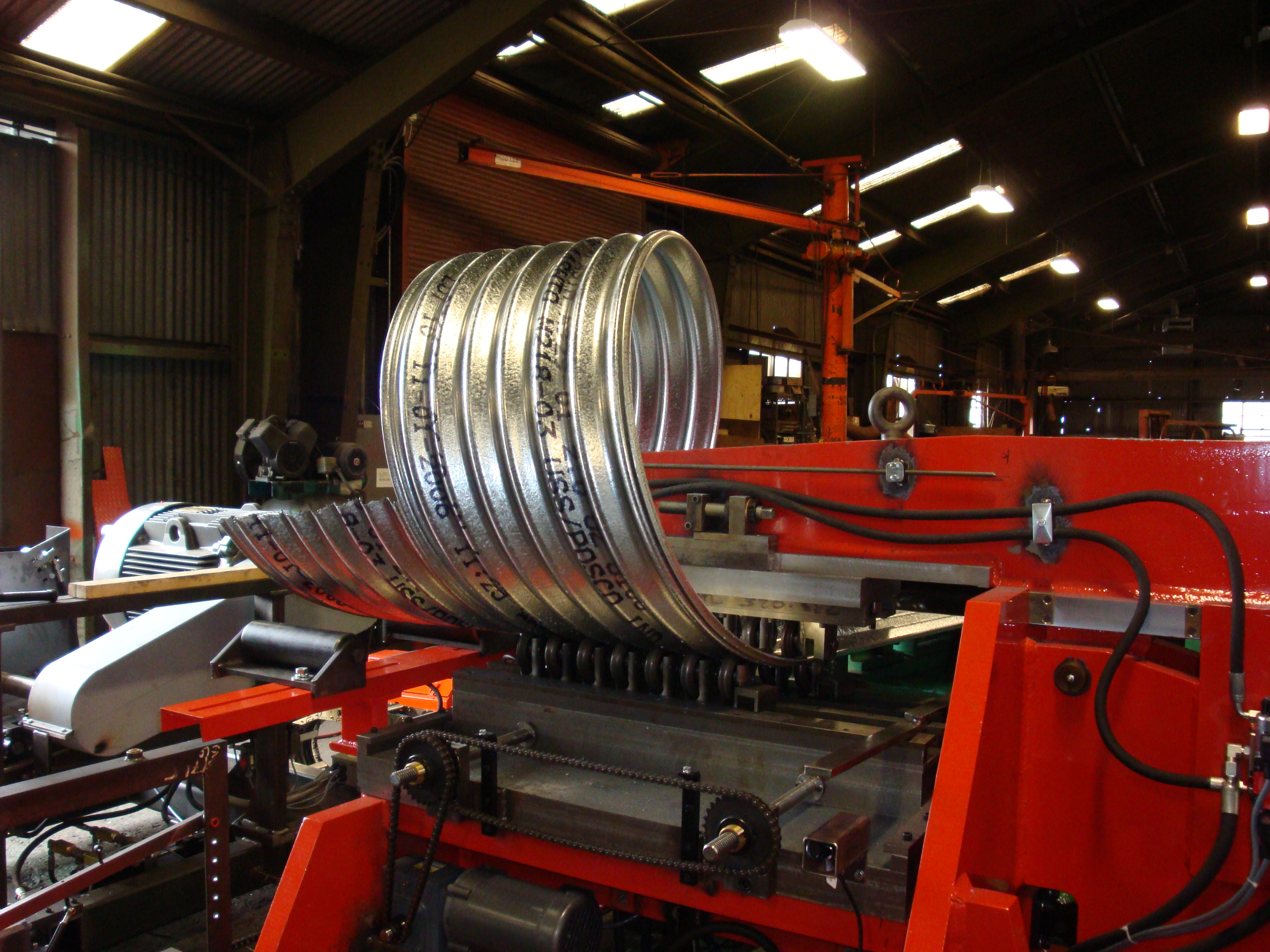

Corrugated Metal Pipe

With the PRD system, you can convert steel coil into many styles of corrugated pipes and meet the vast array of market demands. This includes such uses as highway and railway drainage pipe, and storm sewer pipe and bridge replacements pipe. PRD gives you the most versatility to maximize your success. Large corrugated lockseam pipe...Read More

CEMENT MORTAR COATING

Concrete coating is applied to offshore pipes or to pipe which are going to be laid in ground water. The weight of the concrete coating provides negative buoyancy to prevent floating of pipes. Concrete coating is applied to already anticorrosive coated pipes, like FBE, 3 Layer PE etc. Concrete coating also provide shock absorbance. Main...Read More

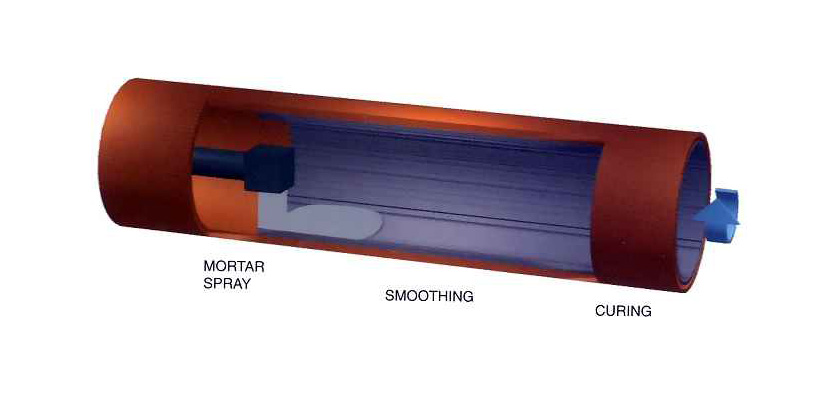

CEMENT MORTAR LINING

PRD’s Cement Lining System provides pipe to convey drinking, waste, raw, industrial, and fire-fighting water. This lining provides tough protection and offers a maximum constant service temperature of 80°C. 1.Surface cleaning 2.Mortar application 3.Mortar tightening 4.Curing All pipe surfaces to be lined are cleaned to remove scale and rust to ensure a secure bond with...Read More

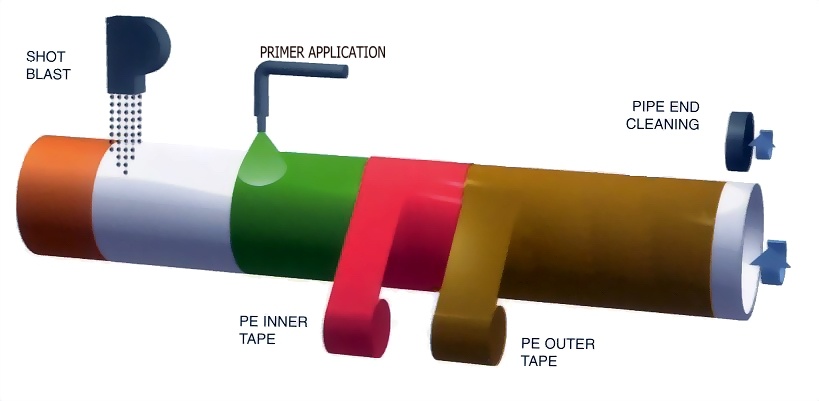

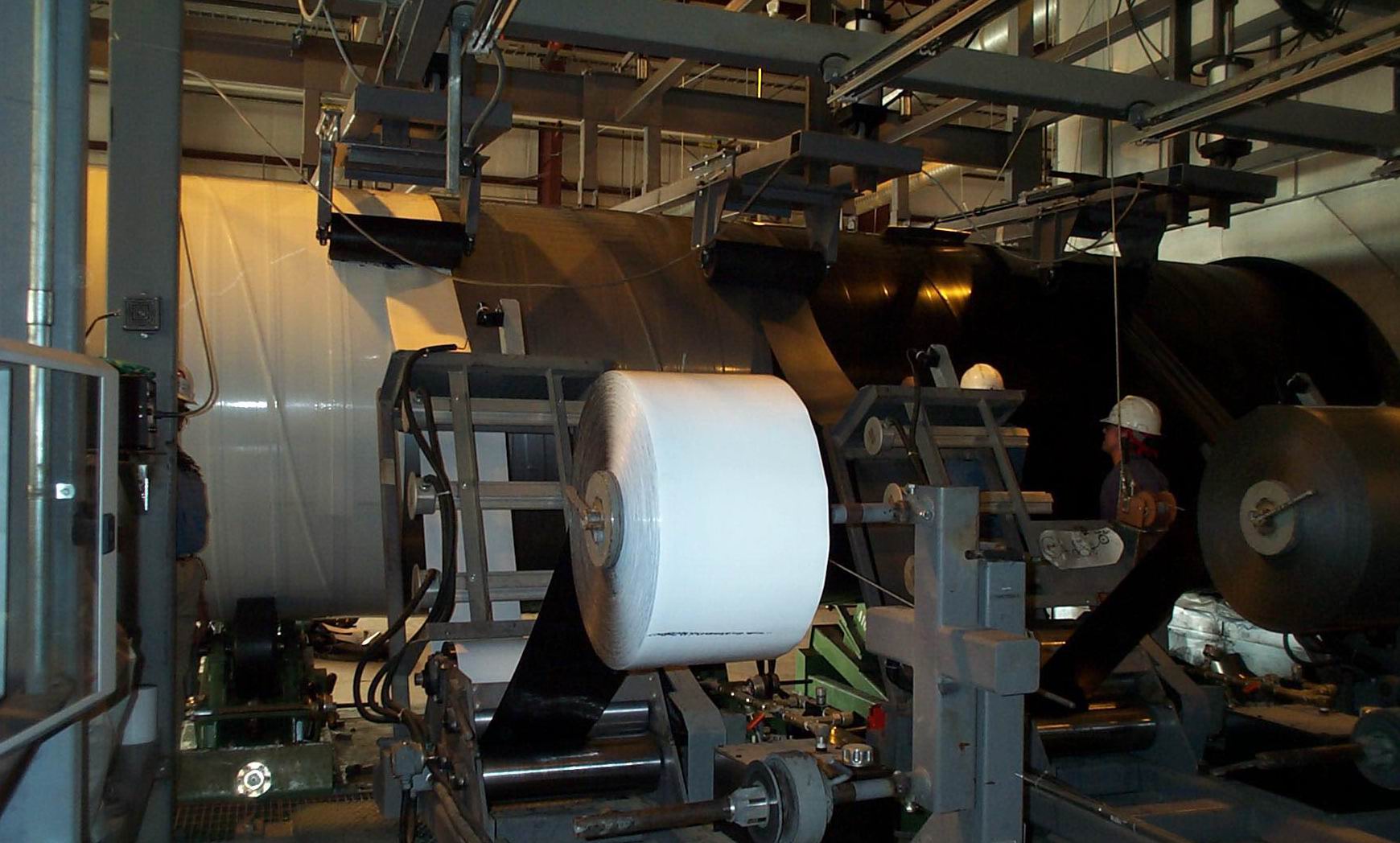

POLYETHYLENE TAPE COATING & WRAPPING

PRD’s Polyethylene Tape Coating Systems offer an alternative to PE extrusion coating. The system produces pipe with ciatings for conveying industrial, raw, waste and drinking water. An Epoxy primer bonds the steel to the adhesive layer. The inner PE adhesive layer offers corrosion protection and tightly bonds to the outer PE coating. A final spiral...Read More

EPOXY SPRAY COATING AND LINING

Epoxy is one of the best materials for coating and lining. Epoxy coated pipe are used in a wide variety of applications, such as potable water pipelines (Service temp. max 140° F (60° C)), casing, piling, and submarine lines. To prevent internal corrosion, Epoxy lining is applied to pipes designed to convey and distribute dry...Read More

3-LAYER POLYETHYLENE COATING

PRD s 3-Layer PE System provides extremely effective defense against the hazards of transportation and installation, the stresses of temperature change in addition to water, organic acids, alkalis, bacteria, and galvanic action. The epoxy primer layer provides reaction sites capable of chemically bonding with the reactive group contained within the terpolymer adhesive layer. This chemical...Read More

MATERIAL HANDLING EQUIPMENTS

CONTENTS – STOP INDEX – LET DOWN – KICK OUT – BRIDGE – CONVEYORS – TURNING ROLLS – ANTI ROLL BACK STOP – PIPE STOP PLATE – BLAST LINE AND COATING LINE CONVEYORS – PIPE TRANSFER CARTS

OFF-LINE ULTRASONIC TEST SYSTEM

CONTENTS 1 – ULTRASONIC TEST EVALUATION METHOD 2 – OFF-LINE WELD TEST 3 – LASER SEAM TRACKING FOR OFF-LINE AND ON-LINE WELD TEST